The D-Type Spring & Loop Grand Action

This is a very short Challen grand piano from the early 1930s.

Piano makers offer a range at various price points to suit different budgets. Small grands like this were the cheapest of a maker's grand piano range, in the UK industry. The total area of the soundboard is smaller than, and the bass strings shorter than, a large upright piano.

"But at least it has a grand piano action, and grand actions are more sensitive than upright actions". Well, not quite. Thousands of small grands like this were fitted with a cut-down version of the grand piano action. This saved both space and costs.

The cut-down version of a grand piano action is called the D-Type Spring & Loop action. Also sometimes called a Simplex action.

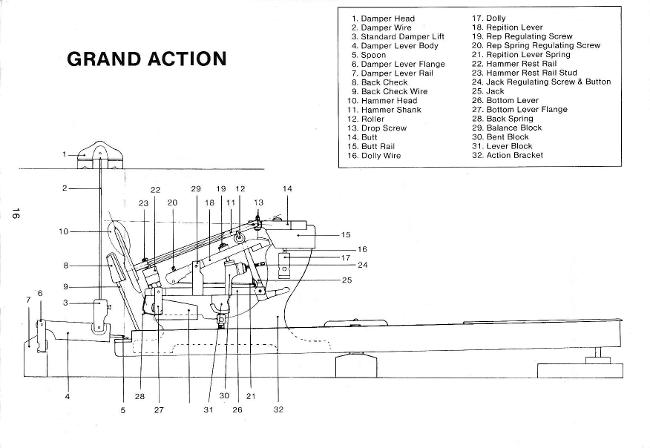

Here is how a modern grand piano action looks This is a three-note model, of a Herrburger Brooks action. They were a large piano action maker and sadly closed down in the 1990s.

The line drawing of a Herrburger Brooks grand piano action is from a 1980s copy of their catalogue (I am unsure whose intellectual property this is, as the company sadly went out of business in the late 1990s).

Herrburger Brooks full repetition grand piano actions as above, had what's called a single-wing repetition spring, which I rather like as it's easy to adjust the tension with the little grub screw. Most action manufacturers now use a different shape, called the double-wing or 'butterfly' repetition spring, as seen in this very nice Petrof grand action model:

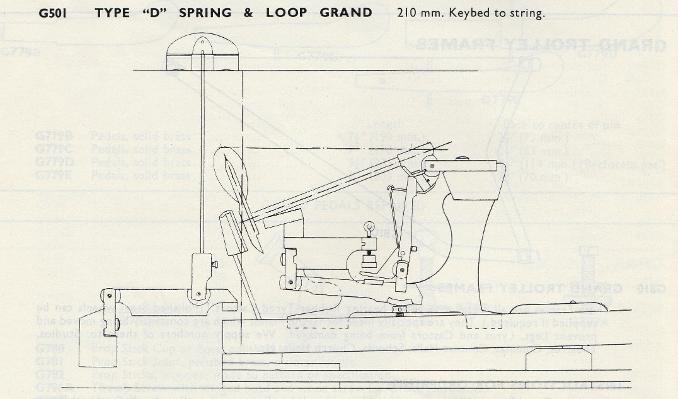

And a line drawing of the D-Type Spring & Loop action, from the 1959 catalogue of piano supply house Fletcher & Newman (reproduced with kind permission):

I don't think I will be giving away important confidential business information if I tell you that the trade price in 1959 for a full grand piano action was 595 Shillings, that's £29.75, while the price for the D-Type Spring & Loop version was 381 Shillings, or £19.05. This is from supply house Fletcher & Newman's 1959 Price List:

Dr Brian Capleton in his excellent little book on piano action regulation says that the D-Type Spring & Loop action was capable of sensitive performance when correctly regulated. But I don't see how it could compare in terms of sensitive repetition and dynamic control, with a properly regulated full grand action.

The D-Type Spring & Loop action stopped being produced in, I believe, 1967, so even the newest of them is now over fifty years old. Most pianos which have them, are much older than that, like the little Challen at the top of this page which is almost 90.

In the small grand pianos which had these actions, other cost savings were made, in terms of choice of timbers etc. So the general quality of these pianos means that it simply isn't worth doing a lot of work on a worn D-Type action. The normal lifespan of a piano is about sixty years before restoration is required. Restoration is generally only for high-end pianos. The little grands with D-Type Spring & Loop actions were budget pianos when new, and are simply not worth significant expenditure now.

Here is an old catalogue illustration of the D-Type:

Note: I am not any kind of expert in these actions. The following suggestions and regulation parameters are gleaned from Dr. Brian Capleton's Piano Action Regulating, and from Pianos, Piano-Tuners and their Problems by George W. Booth.

At the outset it should be pointed out that these actions were fitted to the cheapest grand pianos in a maker's range, and that most of the pianos are pretty old. It is unlikely that many of these pianos would justify the cost of a comprehensive regulation, involving replacement of all worn felt and leather parts.

However, it can certainly be worth doing SOME regulation, to get a piano playing reasonably.

Assuming then that everything is in reasonable condition, and any broken cord loops etc have been replaced:

First, it is important to make sure that all action screws - flanges, rails, action brackets - are tightened. (Not including the grub-screws in the jacks - more on them in a minute). No good regulating all the capstans only to discover that the hammer flange rail is loose and everything sitting in the wrong position (in the time-honoured phrase; Don't ask me how I know!) If screws are loose because the holes in the wood have stripped threads, slightly larger screws could be used or, perhaps more easily, the holes can be treated with low-viscosity CA glue ('superglue') to somewhat reconstitute the wood fibres.

Key levelling and depth of touch: Carried out as normal for a grand action. Dr. Capleton suggests a depth of touch of 9.5mm. There should be some after-touch.

Hammer Blow distance: 47.5mm, set by the key capstans in the normal way. Because of the compact nature of these actions, the capstans are fiddly to access and turn.

Set-off: Dr. Capleton says 2mm in the treble and 3mm in the bass.

Checking: Checking distance 12mm-15mm

Repetition Spring: The tension of the repetition spring is adjusted by turning the grub screw in the jack: Clockwise for greater tension, anti-clockwise for less (the grub screw acts on the spring in a manner similar to the Herrburger Brooks 'Single wing' repetition spring in a full roller action). On releasing from check, the hammer should only rise as far as the set-off distance.

These are the basic parameters. Dr Capleton makes some additional recommendations, for diagnosing faults and I recommend his little action regulating book:

All parts and contents of this website are the intellectual property of David Boyce unless otherwise stated, and may not be reproduced without permission.

© David Boyce 2022.